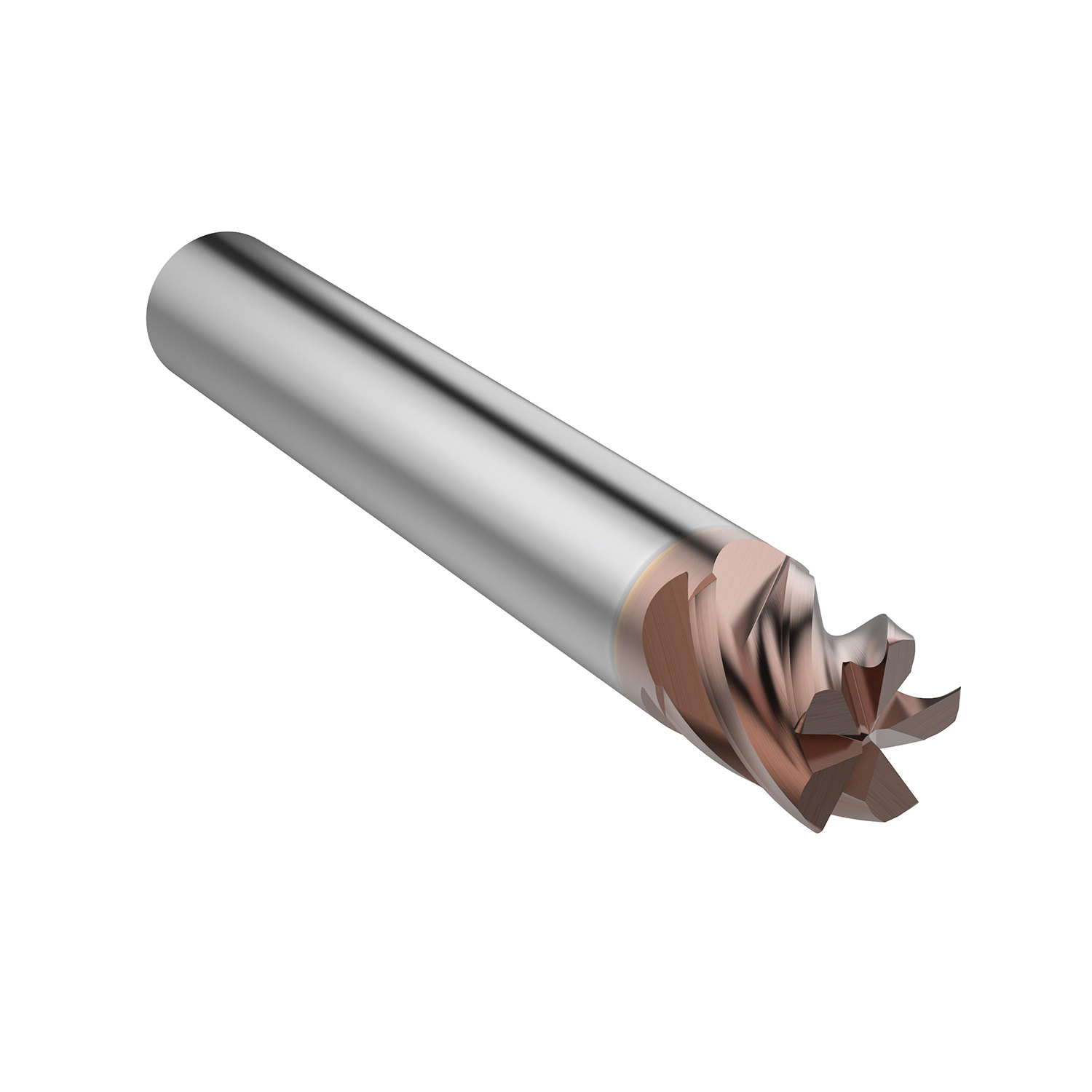

JH790095G2R050.0Z6-HXT JABRO SOLID

JH790095G2R050.0Z6-HXT JABRO SOLID

SEC03127371

03127371

183.60

/ EA

http://schema.org/OutOfStock

/Product/SEC03127371

- Cutter Diameter Decimal Inch: 0.374

- Cutter Diameter Fractional Inch: 3/8

- Cutter Diameter Metric: 9.5

- Material: Solid Carbide

- Overall Length Decimal Inch: 66

- Overall Length Metric: 1676.4

- Shank Diameter Decimal Inch: 0.394

- Shank Diameter Metric: 10

- Type: High Speed T-Slot

- ANSI Code: JH790095G2R050.0Z6-HXT

- Corner Radius: 0.5 mm, 0.5mm

- Country of Origin: NL

- Flute Type: Right Spiral

- Hand Direction: Right Hand

- Has Attributes: Yes

- Has Image: Yes

- Helix Angle: 10 deg, 10°

- ISO Code: JH790095G2R050.0Z6-HXT

- Length of Cut Decimal Inch: 0.079

- Length of Cut Metric: 2.007

- Manufacturer Name: Seco Tools

- Number of Flutes: 6

- Series: JABRO® HSM/Tornado JH790

- Shank Type: Cylindrical

- Surface Treatment: HXT/PVD Coated

Significantly boost knee implant machining speeds to shorten part cycle times by as much as 50% with Seco's new JABRO® CoCr (cobalt chrome) range of solid carbide cutting tools. The industry's first dedicated product line for knee implant machining, this new range includes 9 new advanced geometries and 39 tools, most of which are positioned in the JH Tornado high speed cutting family. These tools combine high speed and high feed machining strategies and are all designed for tibial tray and femoral knee implant parts. The range reduces, if not eliminates, your need for secondary grinding operations, also known as polishing or fine finishing. Exceptional part surface finishes and long tool life result from the tools continuous grades and optimized coatings. You can also maximize machining performance for other medical implant components such as those for hip replacements, bone plates and many others because the new dedicated tooling can be used for machining Ti6Al4V ISO-S12 (3D printed) parts as well.

- Application

Radial and Ramping Applications

/seco_new_150x150.jpg?width=150&height=150)