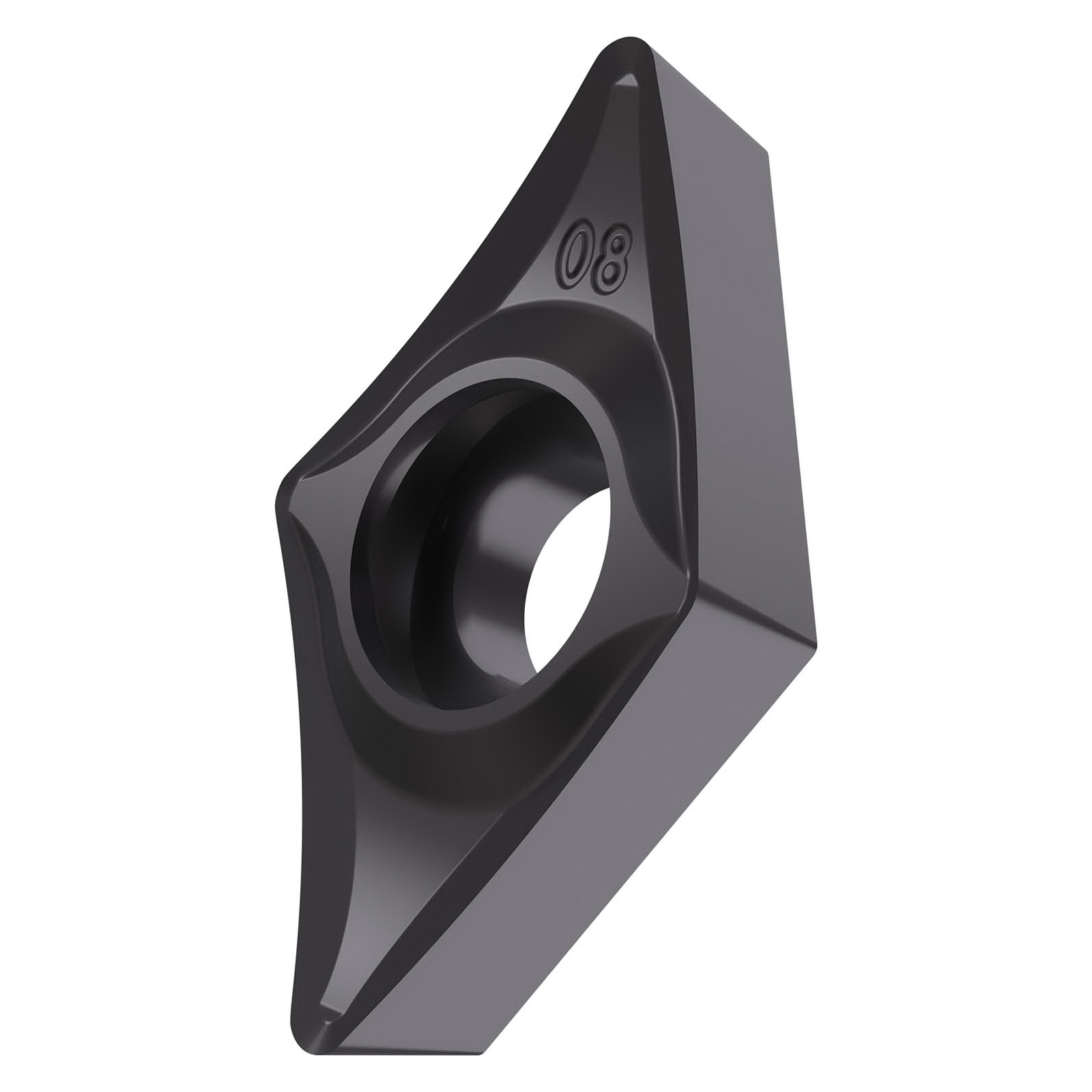

DCGT 32.51-SF3:T6310 TURNING INSERT - POSITIVE

DCGT 32.51-SF3:T6310 TURNING INSERT - POSITIVE

PRA7168565

7168565

13.57

/ EA

http://schema.org/OutOfStock

/Product/PRA7168565

- Applicable Materials: Aluminum, Cast Iron, Hardened Steel, Stainless Steel, Steel and Titanium/Super Alloys

- Chipbreaker: SF3

- Corner Radius: 0.4mm

- Hole Diameter: 0.177in

- Included Angle: 55°

- Inscribed Circle: 3/8in

- Insert Size: 32.51

- Insert Style: DCGT

- ISO Code: DCGT 11T304E-SF3 T6310

- Material: Carbide

- Material Grade: H, K, M, N, P, S

- Maximum Depth of Cut: 2.2mm

- Rake: Positive

- Relief Angle: 7°

- Seat Size: 11

- Shape: Diamond

- Surface Treatment: CVD-AlTiSiN Coated

- Thickness: 5/32in

- Type: 0.457in

- Manufacturer Grade: T6310

- ANSI Code: DCGT 32.51-SF3 T6310

- Has Attributes: Yes

- Has Image: Yes

Single-sided positive turning insert, 55° rhomboid with 7° clearance, inscribed circle diameter of 9.525mm, 3.97mm thick, 0.4mm nose radius, indexing accuracy according to ISO-tolerance class-G, chip-breaker SF3 with rounded cutting edges, in grade T6310, a PVD coated extra fine grained WC-Co carbide within ISO ranges M01-M15 and S01-S15, for fine to medium machining of stainless-steels and super-alloys

- Application

- Item Features

- Standards

Finishing Applications

- T6310 grade high reliability due to special new sintering process

- High wear resistance (new substrate with high strength and hardness)

- PVD coating using triple coating technology, multilayer TiAlN + top layer AlTiSiN with high hardness

- High strength and reliability of the insert during continuous cut

- Excellent durability of the inserts for higher cutting speeds

- Type H ultra submicron substrate

- Cutting edge is extremely strong and stable

- Suitable for applications that require coolant and also for dry machining

- Can potentially be used in unstable conditions

PROP65: This product contains chemicals known to the State of California to cause cancer. For more information: www.P65Warnings.ca.gov